Introduction:

Furnaces fundamentally serve to supply a specified quantity of heat to process fluids. Together with steam boilers they consume approximately 75% of the energy used at petroleum refineries or chemical processing plants. An important factor in the overall efficiency of a furnace is the transfer of thermal energy between the furnace tube and the process fluid.

Reporting

The following reporting structure will be followed during and after performing the cleanign process

- During execution of the Decoking Operation, ARUDRA will provide the client with regular updates of cleaning status and service performance.

- After completion of the Decoking Operation, ARUDRA will prepare a Service Ticket stating Location, Date and Type of Service Performed, Description of Activities and / or Events with their respective Durations.

- The Service Ticket will be issued for the client's approval and serve as a jobcloseout document, a copy of which will remain with the client.

- Delayed Coker Furnaces | Visbreaker Furnaces/Thermal Cracker| Crude Heater | Vacuum heater|Catalytic & steam Reformer | Atmospheric crude & FCC Heater | Hydro treating /hydro cracking Furnace| Pyrolysis Furnace | Hot Oil heater

- Hard coke/scale can be removed | Bi-directional Process, cleaning tool PIG to navigate both side of tube| No hazards chemicals are used| No damage to tube| Increased run length of furnace

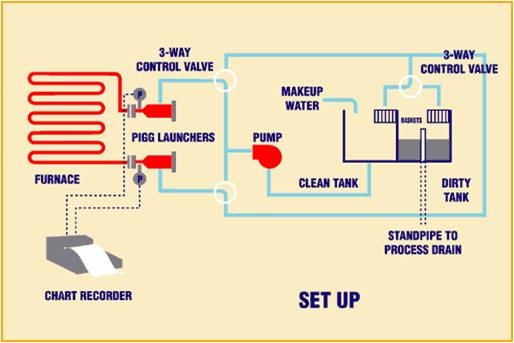

- Double Pumper Decoking unit

- Pig Launchers and Receivers

- Full bore ball valves

- Temporary High and Low Pressure Hoses

- Personnel - each crew consists of supervisors and operators.

- Water : 5000 Liters / Hour |Diesel Fuel: 7000 Liters/ 12 hours| Foam Pigs|Cleaning Pigs|

Fired Heater Typically Pigged

Advantages

Equipment : The equipment setup for the decoking operation includes:

Operation Consumables

During the decoking operation we use